Premium Tube Mill Technology

Engineering the Future of Manufacturing

Leading ERW tube mill manufacturer since 1989. Delivering custom, high-precision equipment derived from 30+ years of expertise.

Next Slide

Browse Our Products

What Does ERW Tube Mill Line Mean? ERW (Electric Resistance Welded) tube mill line is a continuous production system that manufactures welded steel pipes/tubes by forming and longitudinally welding coiled steel strips through high-frequency electric resistance welding.

Our customers produce pipe & tubes, we supply the equipment and machinery.

Entry Section

SRET can provide all equipment for the entry section, including uncoiler, flattener, shear end welder and horizontal spiral accumulator.

Learn More

Forming & Sizing Section

Uses a series of precision rolls to gradually bend the steel strip into a specified cross-sectional shape (e.g., round, square, rectangular).

Learn More

Welding Section

High Frequency (H.F.) welding is a technique used to longitudinally weld the seam, where the edges are being squeezed together into closed circular / square / rectangular shape in forming process.

Learn More

Cut Off Section

CNC cut off is a new-generation high-tech equipment on ERW tube mill line. It's able to cut on line in form of milling the medium and large tube products accurately into pre-set cut length.

Learn More

Finishing Section

In order to meet the needs of customers, SRET provides Straightener, End Facing Machine, Hydrostatic Tester and Automatic Stacking & Strapping Machine.

Learn More

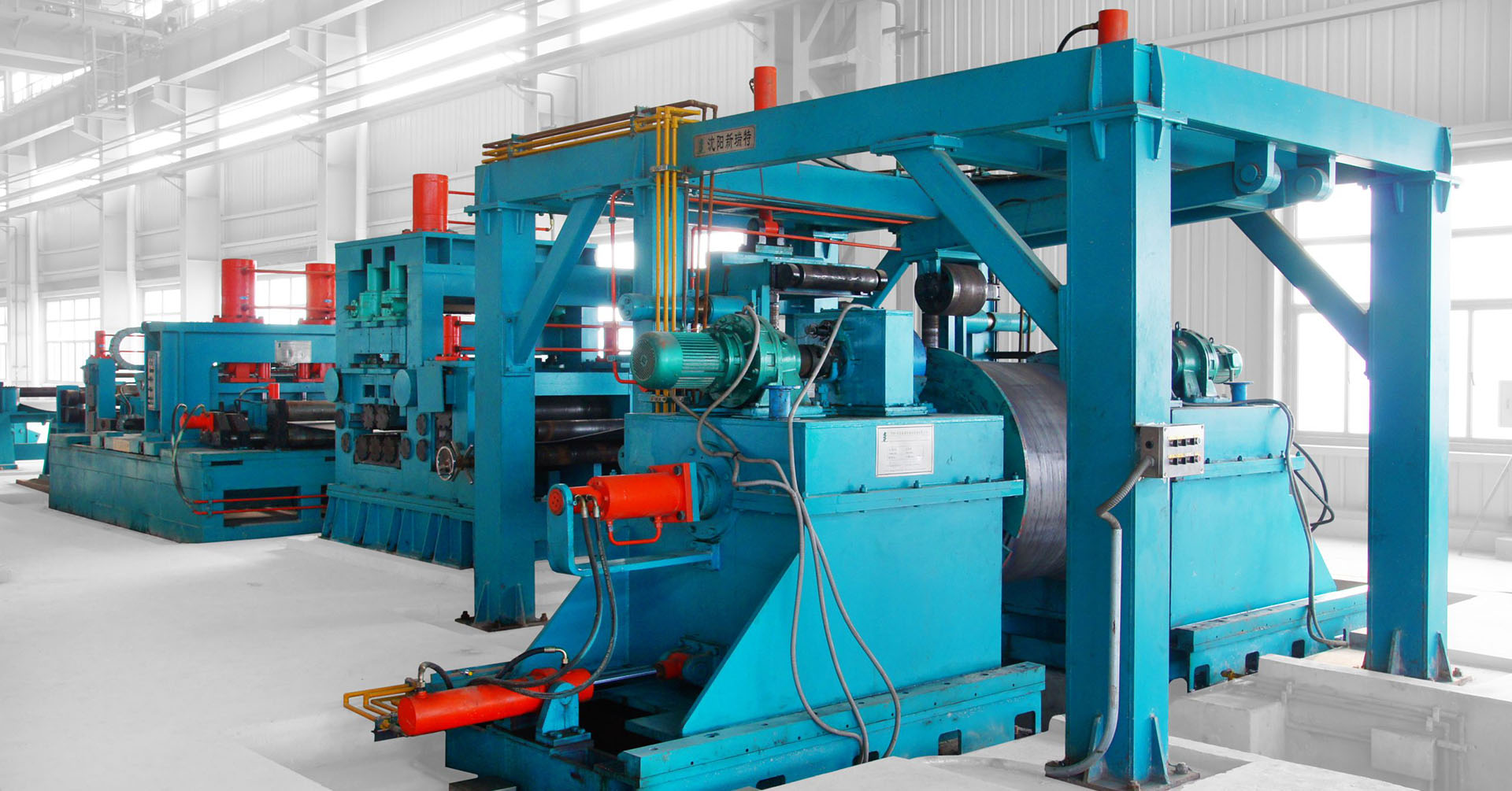

Strip Processing Line

Strip Processing Line include slitting line and cut-to-length line, designed and manufactured to cut an entry raw coil into narrow coils or sheets.

Learn MorePrecision Engineering for Superior Tubes

SRET Equipment Technology Co., Ltd. is a premier manufacturer specializing in ERW tube mill lines. With over three decades of experience, we combine traditional craftsmanship with cutting-edge technology to deliver equipment that defines industry standards.

Learn more about our legacy

Why Choose SRET?

Advanced Technology

State-of-the-art solid state high frequency welding.

Custom Solutions

Tailored equipment designs to meet specific production needs.

Global Trust

Exported to over 20 countries with verified reliability.